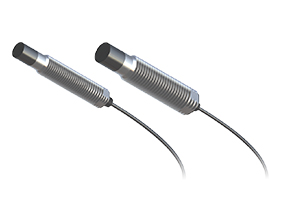

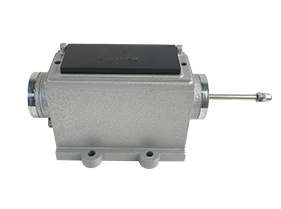

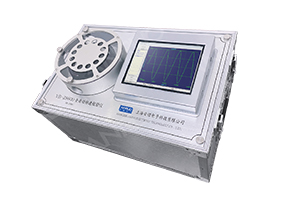

VB-D94 series of positive and negative double-channel speed sensor is installed on the speed measuring end cover, induction of the magnet on the convex teeth or concave groove, the corresponding upper and lower level, used to detect the speed of the axle, linear speed. The sensor has good low frequency and high frequency characteristics, low frequency up to 0Hz, can be used for zero speed measurement of rotating machinery, because the sensor can give two speed signals with a certain phase difference, so can progress positive and negative discrimination; The high frequency can be as high as 20KHz, which can meet the requirements of high speed measurement in most industrial fields. The sensor has no contact with the measured gear, no wear, easy installation, and the output waveform is a square wave with duty cycle of about 50%.

· Frequency response characteristic:0~20kHz

· Number of output channels: dual channels

· Output waveform: square wave, rising and falling edge time12us土40%

· Output amplitude: high level:Ub-[1.8V土40%] / Low level:

· Pulse duty cycle:50%士25%

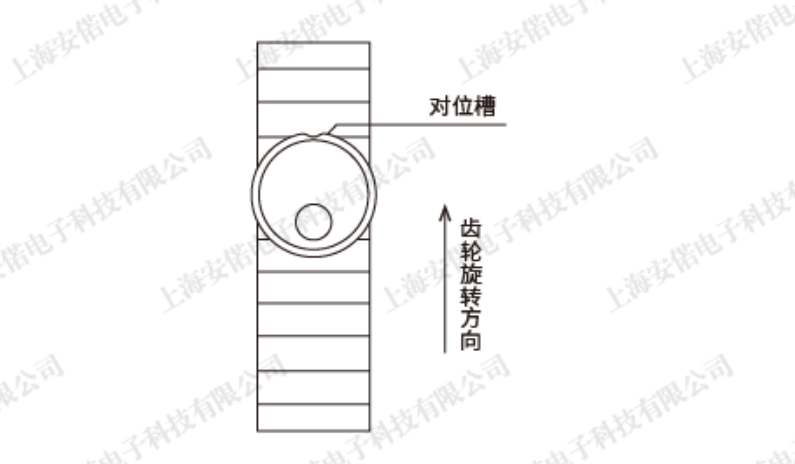

· Phase difference:90土30°[First channel lead] Note: Depending on the installation method and the rotation direction of the rotating parts, this parameter applies to the installation method illustrated in Figure 4 of this manual

· Load ability:±20mA[max]

· Output impedance:47Ω

- ■ Electrical characteristics

· Power supply polarity protection: Yes

· Output short-circuit protection: Yes

· Insulation strength:1000V 50Hz,1min(Channel and enclosure)

- ■ Working environment

· Working power supply:Ub=15VDC±30%[8V~28V]

· Power consumption current:≤35mA

· Operating temperature:-40°C~125°C(head]

· Vibration resistance: vibration(10Hz~2KHz]30g,impact100g

· Airtightness:IP68

- ■ Installation requirements