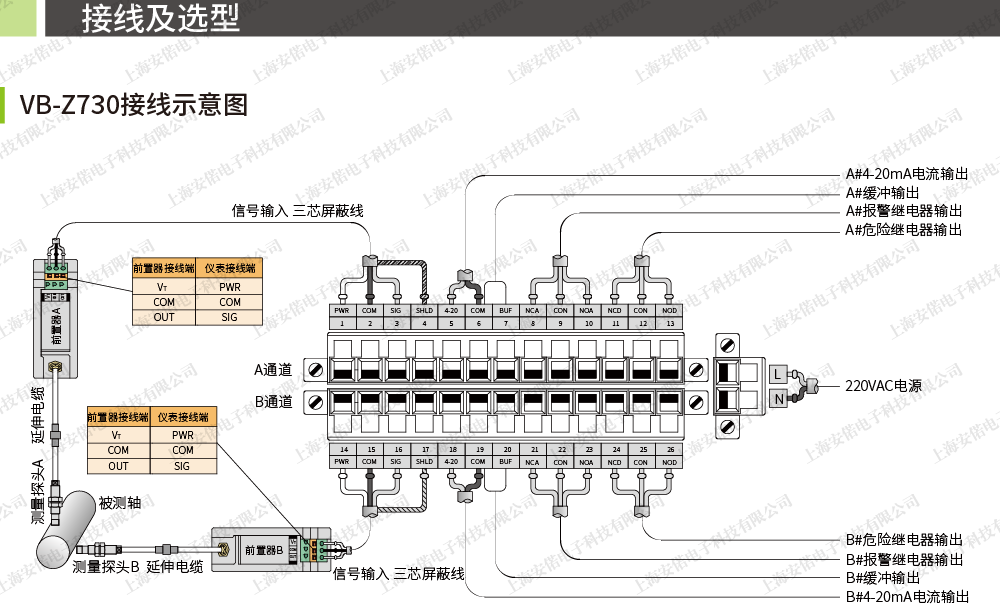

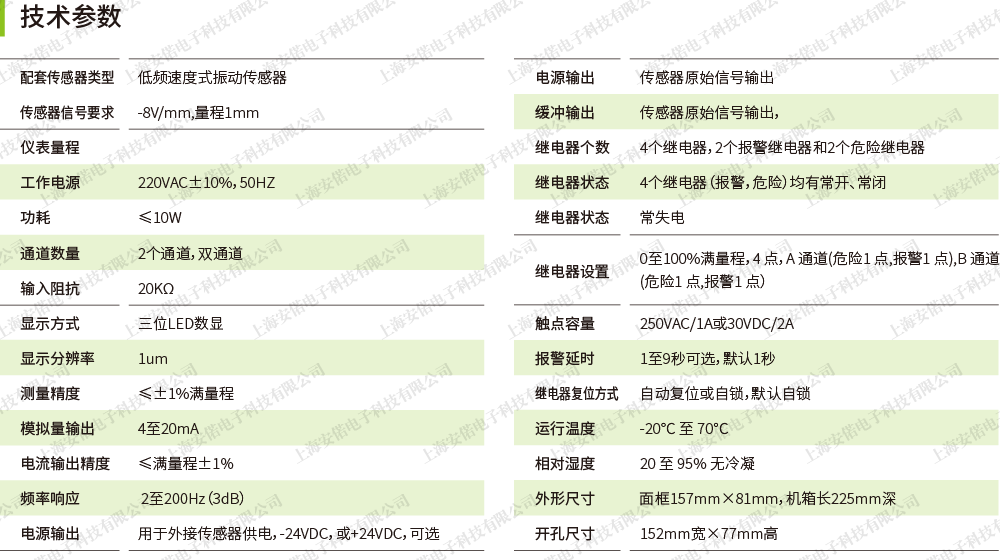

Excessive or specific forms of vibration will occur when the machine fails. Of all vibration types, absolute bearing vibration is the easiest to measure and refers to the rapid vibration of the housing (bearing bush and bearing seat) relative to a fixed reference point in space. Low frequency vibration sensors can be used to measure the horizontal and vertical directions of the housing. Absolute bearing vibration monitoring is the most basic and extensive protection means for most rotating machinery. VB-Z730 water machine vibration monitor is a dual-channel vibration monitor instrument. The two channels work independently, display independently, and input signals from two speed sensors respectively. This is an ideal monitoring and protection instrument for many small and medium-sized rotating machines, especially those with ball bearings (shaft vibrations are more likely to travel to the housing).

· Input power protection function.

· You can set alarm parameters, range, relay delay and other parameters by pressing the button.

· The set parameters will not be lost after power loss.

· Sensor break detection, sensor break, block relay output, OK light out.

· Sensor power current limiting protection.

· Sensor signal buffered output.

· Lock the relay output within 10 seconds after power-on.