VB-Z412 programmable dual channel axial displacement monitor is used to continuously monitor and measure the position of the rotating shaft in the axial direction with respect to the thrust bearing of the rotating machinery.

VB-Z412AThe programmable dual-channel axial dilatation monitor is used to measure changes in the relative position of rotating machinery caused by inconsistent expansion of the rotor with respect to the cylinder.

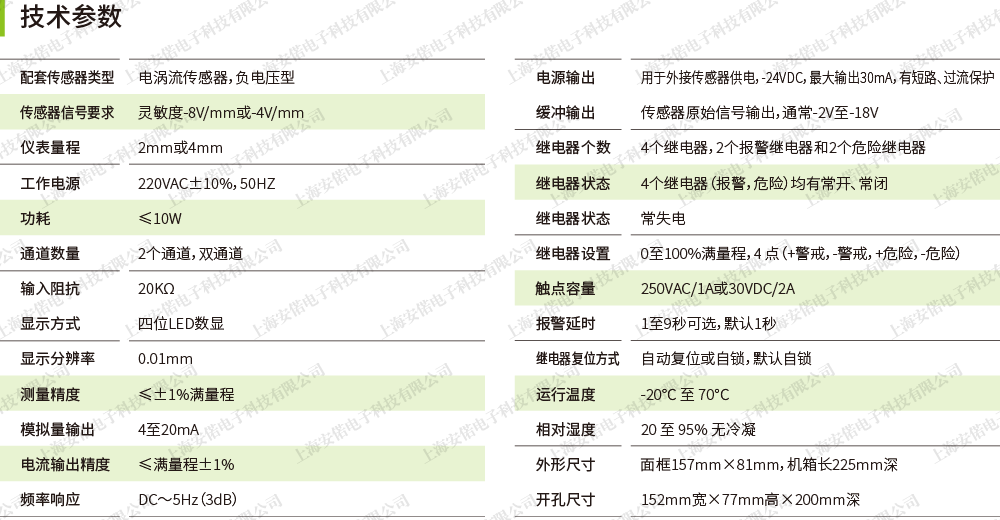

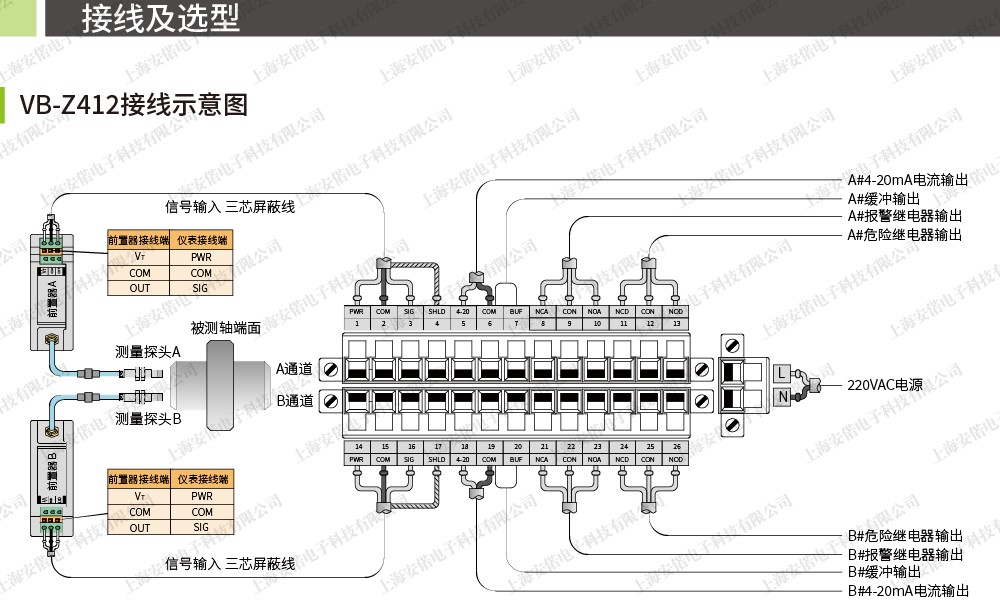

VB-Z412 and VB-Z412A can be widely used in the electric power, metallurgy, petrochemical and paper industries of large rotating machinery (such as steam turbine, water turbine, turbine compressor, fan, centrifugal pump, etc.) axial displacement monitoring and protection control. VB-Z412 dual channel axial displacement monitor is equipped with eddy current sensor.

· Input power protection function.

· You can set alarm parameters, range, relay delay and other parameters by pressing the button.

· The set parameters will not be lost after power loss.

· Zero correction function, ensure the mechanical zero and instrument zero consistent.

· Sensor break detection, sensor break, block relay output, OK light out.

· Sensor power current limiting protection.

· Sensor signal buffered output.

· Lock the relay output within 10 seconds after power-on.