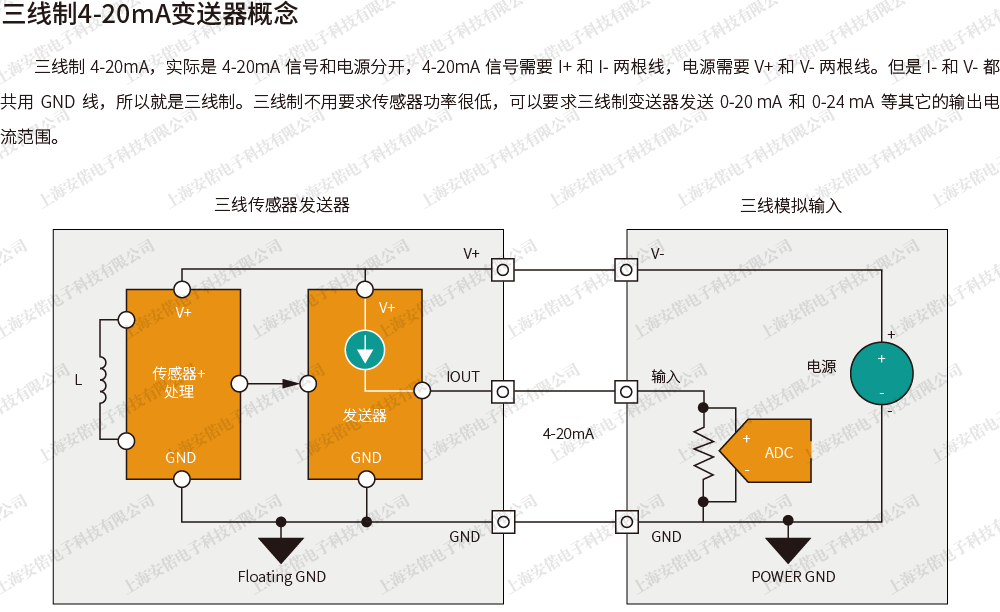

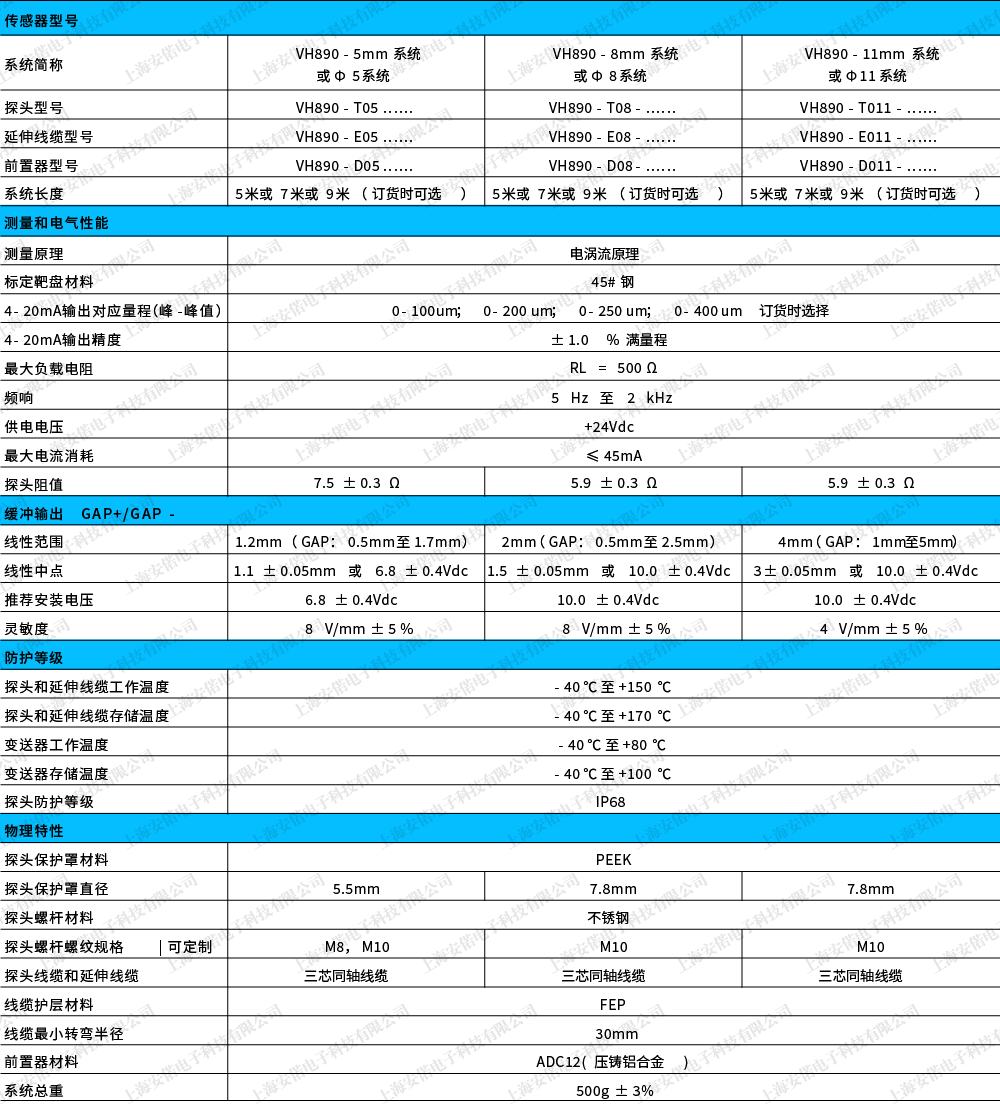

VH890 three-wire shaft vibration transmitter converts the peak value of vibration displacement into 4 to 20 mA industry standard signals, providing vibration monitoring protection and alarm for machinery.

VH890 three-wire shaft vibration transmitter is mainly used to test the vibration of mechanical rotating shaft. It can be very convenient and industrial field existing PLC or DCS system directly connected, no additional instrument conversion is required, simple and convenient for rotating equipment to provide vibration monitoring protection.

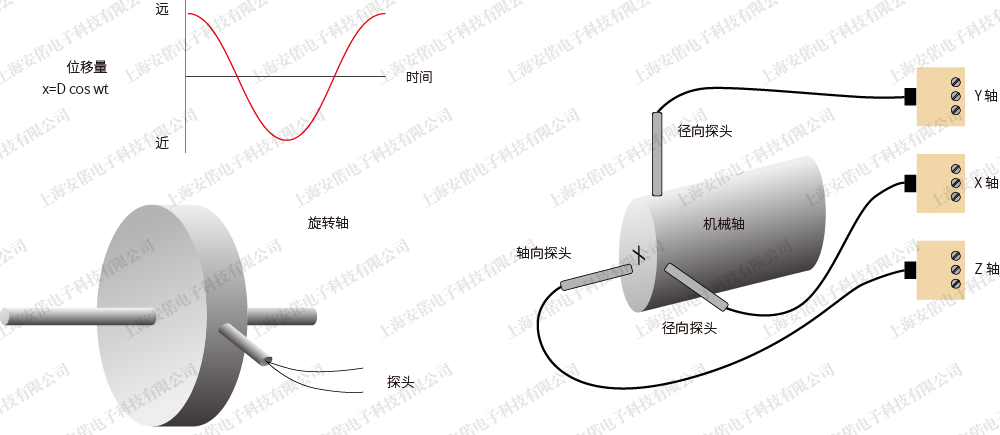

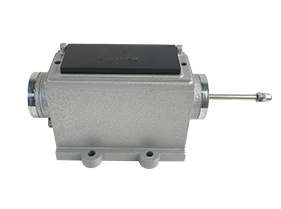

VH890 three-wire shaft vibration transmitter is essentially an eddy current sensor. It is composed of probe, extension cable and transmitter. Its probe is in the form of a screw, similar to a probe. The probe is inserted into the machine, located just above the surface of the rotating shaft, the probe is packaged with a coil, through high-frequency AC signal excitation, the magnetic field generated by the coil induces eddy currents in the metal shaft, the closer the shaft is to the probe, the closer the magnetic coupling between the shaft and the probe inside the coil, the stronger the eddy currents. The transmitter senses the distance of the shaft by the strength of the eddy.

When the distance between the measured object and the probe changes back and forth, that is, the measured object vibrates, and the transmitter can convert the peak-to-peak value of this back and forth displacement change into 4 to 20mA current signal as required.

For each bearing to be monitored, there will be one or two radially mounted sensors. If only one sensor is installed, it is usually located at the top center on the bearing. If two sensors are used, they are usually installed at a 90° split Angle.