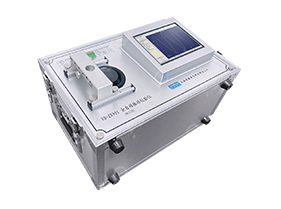

Instrument products in the use of flammable, explosive hazards will cause great harm to the personal safety of the operator, so the enterprise for explosion-proof technology training is indispensable. In 2015, instrument and instrument explosion-proof technology training class was established by China Instrument College to cultivate professional explosion-proof technology talents for instrument and instrument industry. Next we mainly to pick up the basic content of instrument explosion-proof technology training, hope to help you.

First, flameproof explosion-proof instrument installation and use requirements

Flameproof type explosion-proof structure is the circuit and terminal of the instrument are all placed in the flameproof housing, the strength of the case is large enough, the case interface clearance is deep enough, and the maximum gap width is narrow enough. This kind of instrument even if the accident caused by sparks inside the case explosion, also will not cause the explosive gas explosion outside the instrument. Flameproof meters are available in Class 1, Class 1 and Class 1, Class 2 establishments. The instrument can ensure safety during normal installation and maintenance, but it loses its explosion-proof performance when the shell is opened, so it cannot be opened for inspection and adjustment under energized operation. After long-term use of the instrument, it is difficult to maintain the gap of the explosion-proof case because of wear and tear, so it will gradually lose the explosion-proof performance. Flameproof instruments cannot be used in explosive environments with high grades and groups.

Requirements for installation and use of flameproof explosion-proof instrument:

1. The product shell is equipped with a grounding terminal. Users should be grounded reliably when using the product (if the power supply voltage is greater than 36V, the internal grounding must be connected reliably).

2. There should be no harmful gases corrosive to aluminum alloy at the installation site.

3. The maximum temperature of the explosion-proof shell shall not exceed 1300C.

4. Maintenance and battery replacement must be carried out in a safe place; Only when no combustible gas is confirmed at the installation site can maintenance be carried out.

5. When installing, using and maintaining the product, users must comply with the relevant provisions of GB50058-92 "Code for Design of Electric Devices in Explosive and Fire Dangerous Environment" and "Electrical Safety Regulations for Explosive Dangerous Places of the People's Republic of China".

6. When the external power supply or external signal is used, the cable is rubber, with an outer diameter of 8~ 8.5; If external power supply and external signal are not used, the cable outlet should be sealed with a blind plate.

7. Flameproof type is used in dangerous places below Zone 1 of combustible gas of Class II, Class B, T4.

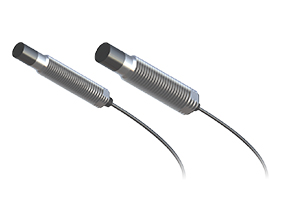

2. Installation and use requirements of intrinsically safe explosion-proof instrument

Intrinsically safe circuits generate sparks and reach temperatures that do not cause explosive gas mixtures to explode under normal and fault conditions. Normal state refers to the working state of the electrical equipment under the specified design conditions, including normal open and close circuits. The fault state refers to the short circuit, open circuit, ground, and power supply faults that occur due to accidents. Modern intrinsically safe explosion-proof refers to the explosion-proof of the whole automation system, such as DDZ-Ⅲ electric unit instrument combination. The explosion-proof system includes two kinds of intrinsically safe and non-intrinsically safe circuits. The intrinsically safe circuit is installed in the dangerous place (site), and the non-intrinsically safe circuit is installed in the non-dangerous place (control room). The explosion-proof safety grid is adopted between the two to prevent excessive energy from entering the dangerous place. The whole instrument has intrinsically safe and explosion-proof performance.

Installation and use requirements of intrinsically safe explosion-proof instrument:

1. The product shell is equipped with a ground terminal. Users should be grounded reliably when using the product.

2. When the external power supply is used, it must be matched with the associated equipment (safety grid) identified by the explosion-proof certification body to form the original safety explosion-proof system before it can be applied in the corresponding explosive dangerous places. The connecting cable shall be shielded cable, the shielding layer shall be grounded in a safe place, and the cable parameter distribution shall be controlled within 0.05uF/1mH.

3. The safety grid must be installed in a safe place, and its installation, use and maintenance must comply with the relevant provisions of the safety grid instruction manual.

4. Users are not allowed to replace electrical components in the product at will.

5. When installing, using and maintaining the product, users must comply with the relevant provisions of GB50058-92 "Code for Design of Electric Devices in Explosive and Fire Dangerous Environment" and "Electrical Safety Regulations for Explosive Dangerous Places of the People's Republic of China".