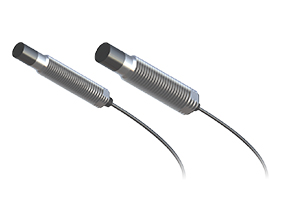

Water flow sensor uses Hall effect of Hall element to measure magnetic physical quantity. At the same time, a 5V DC voltage is applied and the direction of current is orthogonal to the direction of magnetic field. When water drives the magnetic rotor to rotate through the turbine switch housing, rotating magnetic fields of different magnetic poles are generated, magnetic induction lines are cut, and high and low pulse levels are generated. Since the output pulse signal frequency of the turbine flowmeter is directly proportional to the speed of the magnetic rotor, and the speed of the rotor is directly proportional to the water flow rate, the gas water heater is started according to the size of the water flow rate.

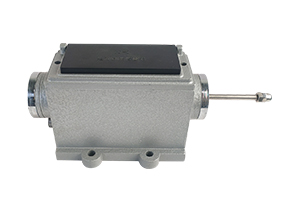

1. Layout method

Internal layout is the best choice of reverse thrust turbine flow sensor, because the layout within a certain flow scale can make the impeller in the floating state, axial contact point is not present, no end surface conflict and wear, can prolong the service life of the bearing; Regarding the flow sensor of the horizontal layout device, it can be connected with the pipe by flange connection, thread connection and clamping connection; The flow sensor of the straight layout device can only be threaded.

2. Accuracy level

The accuracy level of water flow sensor is usually relatively high, and in general, the higher the accuracy, the more sensitive it is to the operating environment of the site. From the point of view of economic benefits, do not blindly seek high accuracy level. On the occasion of large runoff, such as the west to east gas transmission project, it is necessary to select high-precision sensors, and on the occasion of small transport volume and need to measure, it is possible to select the usual turbine flow sensor.

3. Stress loss

The smaller the pressure loss, the smaller the energy consumption of gas in the process of activity, so as to save energy, reduce the transport cost, improve the utilization rate. Therefore, turbine flow sensors with small pressure loss should be selected as far as possible during selection. In general, the turbine flow sensor with semi-ellipsoidal front drainer has less pressure loss than that with cone front drainer.

Step 4: Density

The stability of density has a great impact on the measurement accuracy of the water flow sensor. On the occasion that the density is often changed, it is also necessary to adopt the method of correcting the flow coefficient, especially on the low flow area.

5. Traffic scale

The selection of water flow sensor flow scale directly affects its accuracy and service life, it also determines the selection of flow sensor caliber. The size of the flow is usually selected in accordance with the following principles: the minimum flow should be greater than or equal to the minimum flow that can be measured on the surface, and the maximum flow should be less than or equal to the maximum flow that can be measured on the surface; On the occasion of uninterrupted operation less than eight hours, its maximum flow should be about 1.3 times the maximum practice flow; For the occasion of uninterrupted operation exceeding eight hours, the maximum flow rate shall be more than 1.4 times the maximum practice flow rate; The minimum flow should be 0.8 times of the minimum practice flow as the best.

More sensor selection, such as: eddy current displacement sensor please call: 13801968092